Research & Development

Flow Assurance

LICengineering has investigated, designed and tested/demonstrated flow assurance issue for a wide number of cases.

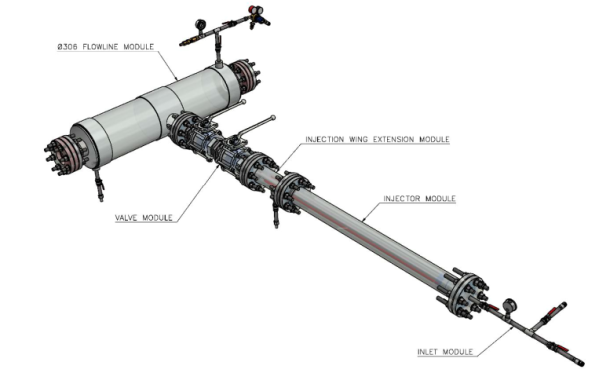

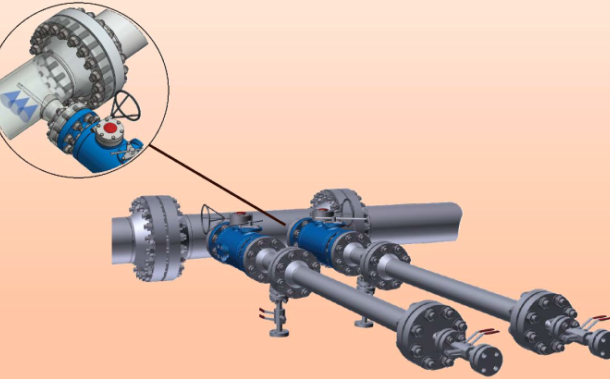

Design of On-Stream H2S Scavenger Injector

An injector demonstrator has been designed built and tested by LICengineering A/S. It is a new chemical injector for use in process plant flowline applications. The injector achieves injection from a number of nozzles creating a spray haze over the full flowline conduit. The injector has an injection wing which can be inserted and removed through double block and bleed valves into a high-pressure flowline system without interruption of the process flow as the double block isolations are maintained. The injector is developed with a focus on H2S removal by use of direct injection. The development is carried out by LICengineering A/S as part of the EUDP supported H2SMAN project conducted under the Offshore Energy Cluster in Esbjerg.

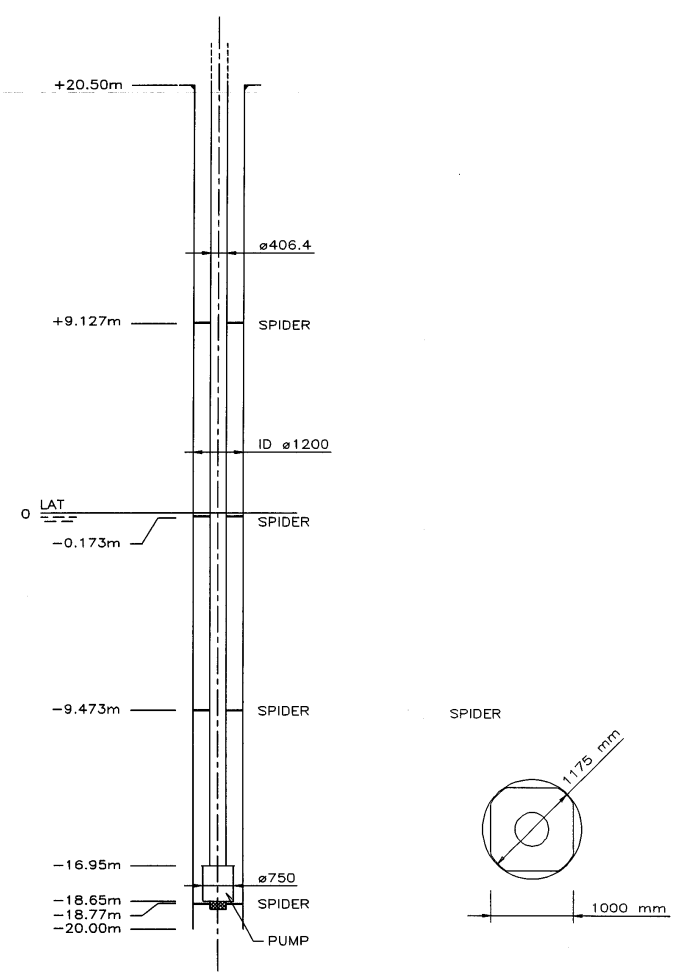

Fluctuations in Fire Water Pump Caisson

In relation to flow assurance, LICnegineering has also performed projects about fire water pump caissons. In these projects the object was to analyse the fluctuation in the fire water pump caisson and enure that cavitation in the fire water pump would not take place. Cavitation might occur due to wave and pump induced fluctuation in the annulus in between the caisson and the water lift pipe in the caisson.

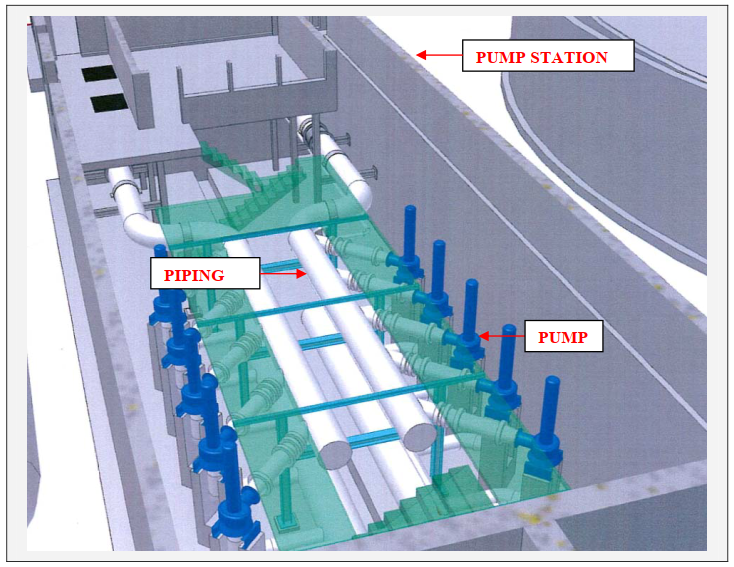

Water Hammer & Loads in Piping

In relation to flow assurance, LICnegineering has also performed projects about comprising calculations of water hammer and the resulting static and dynamic loads on the piping structure. A specific project was a planned installation which included 5 pump stations. Each pump station included 2 groups of 5 pumps each. Each group of 5 pumps was via 1 pipe connected to a downstream basin. During operation maximum 4 pumps in a pump group were pumping at the same time.