Testing Services

LICengineering has regularly been engaged to carry out testing services for offshore and onshore equipment. Work includes FAT testing of LIC supplied components, testing of cables to determin the structural properties, testing related to insurance and root cause investigations for structural failures and testing of malfunctioning transport equipment for onshore road transport of very heavy components.

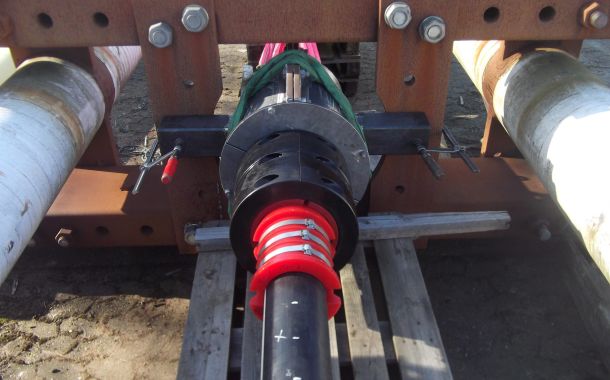

Left foto: Testing of failed subsea power export cable, failure due to bird caging during installation. Right fotos from the top: 1) Determination of dynamic properties for offshore free hanging cables. 2) Test of frictional hold-back clamps for failed subsea cable protection system (CPS). 3) Full scale test of LIC designed seal arrangement for platforms in large offshore monopile towers.

LICengineering has a 12 m long horizontal testrig based in Esbjerg which allows us to carry out structural cable testing for windfarm offshore array and export cables. We also have possibilities for vertical suspension to determine cable dynamic behaviour. LIC has delivered testing sevices for a number of specific jobs relating to offshore/subsea cables in the North Sea. Some of the tasks have been:

- Cable mechanical static properties and dynamic behaviour

- Root cause identification for failed cables during pulling operations, cable twist

- Testing of cable protection systems (CPS) including repair engineering

- Cable clamp capacity

- Clawloks connector, steel-steel connection system, CPS connection to J-tube/MP hole

- Testing and design of external and internal J-tube systems

- Integration testing including testing of Airtight platform (ATP) solutions

- Subsea epoxy grouting tests

- Scour tests