WTG Support Structures

LICengineering is involved with design and engineering of steel foundations for large offshore windfarms including supports for wind turbine generators (WTG´s). Design works includes hydrodynamic, structural and installation design as well as cable protection, cable routing and cable dynamics analyses.

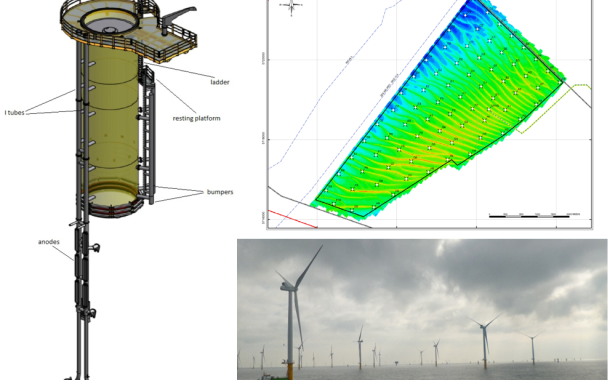

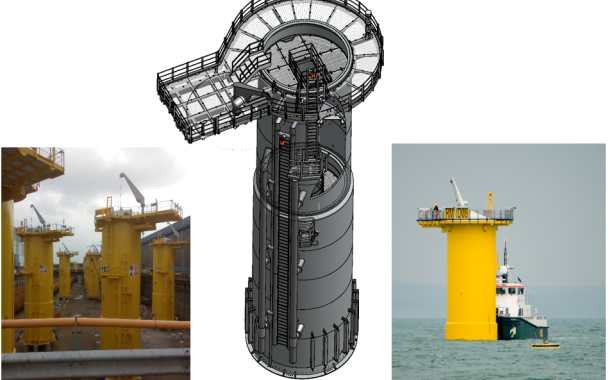

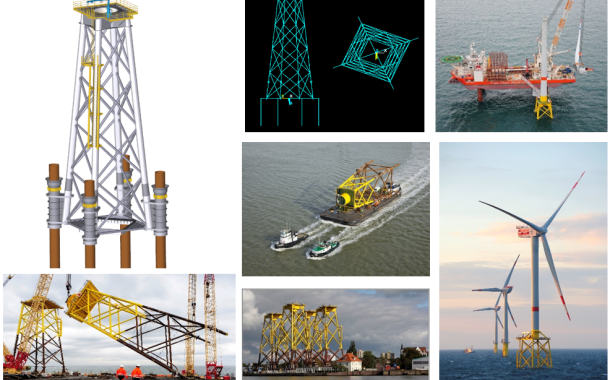

Left foto: Transition piece line-up ready for offshore installation. LICengineering pioneered the design for the grouted connections at Blyth and North Hoyle offshore UK, as well as provided the first design of TP-less solutions – for the Scroby Sands windfarm. Right fotos: LICengineering designs special TP´s including such as retractable J-tubes and cage structuresLIC designed jacket structures and provides all related hydrodynamic and geotechnical/piling design as well as various special engineering within hydraulic systems and sealing systems for internal platforms

LICengineering provides support during all phases of the design of offshore wind turbine generator support structures, starting from site investigations, conceptual through to detailed design, detailed drawings, fabrication, transport, installation and in-service until decommissioning.

LICengineering provides the following services:

- Conceptual and detailed design services for secondary and primary steel

- MP detailed partly automated design program including the full geotechnical design

- Pile driving analysis

- Flange FEM analysis including detailed bolt modelling, pre-tensioning, driving, in-situ and fatigue utilization

- Corrosion protection active/passive systems

- Scour protection/analysis

- Detailed fabrication drawings, monopile, jacket structures, bucket foundations

- New solutions/innovative design

- Special engineering: structural, hydrodynamics, cable dynamics/tie-in, geotechnical analysis

- Example projects: Blyth Harbour, Scroby Sands, North Hoyle, Northwind, Rampion, Kriegers Flak, Vesterhav Nord/Syd, Dafeng, Changua, Xuven, Hai Long, and Dogger Bank

- Review and evaluation on ad hoc basis

The TP-less Scroby Sands design featured and external cage structure and a hanging internal airtight platform (ATP). This ATP was onshore installed in a damped suspension arrangement prior to the offshore pile driving operation. Recently, we have developed a internal ATP with a Client (patent pending), which saved lots of time during offshore installation of the windfarm foundations.