Topsides

Design activities include topside interfaces, riser and conductor supports, spools and supports, caisson repair, deck extensions, escape ladder, platform bridge bearings, temporary pull-in winch arrangements, and occasionally full topside structures and subsea valve control systems.

Structural and Piping Elements

LICengineering has carried out a variety of jobs relating to oil and gas fixed platform topsides. The work includes detailed design of topside support structures for monotower platforms in marginal fields development in the North Sea. Furthermore, detailed design of deck extensions has been prepared.

LIC activities also includes process related activities in relation to pipelines: flow assurance stationary/dynamic analyses for interlinked platform oil flow, pump tripping, valve operations, water hammer effects, pre-commissioning planning, pipeline pigging and isolation during temporary conditions.

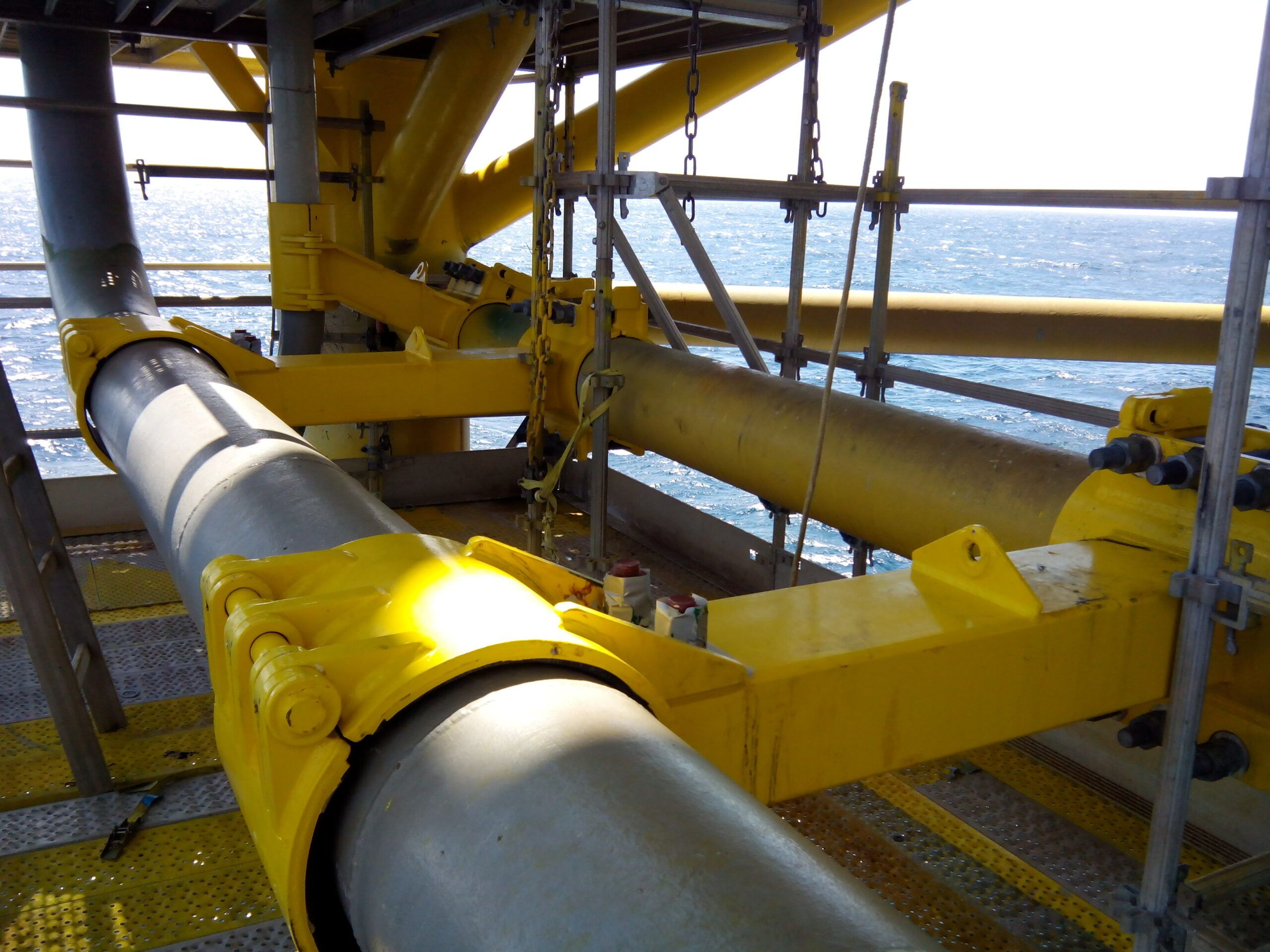

Topside Piping

The topside riser spools incl. supports are sometimes part of our design scope. The topside guide supports are also part of the structural verification FEM activities.

Topside Tie-in Spools

The riser tie-in spools are sometimes part of our design scope. The spool interfaces are also part of the structural verification FEM activities.

X-mas Tree Supports

Design of support frames for X-mas trees in early production set-up.

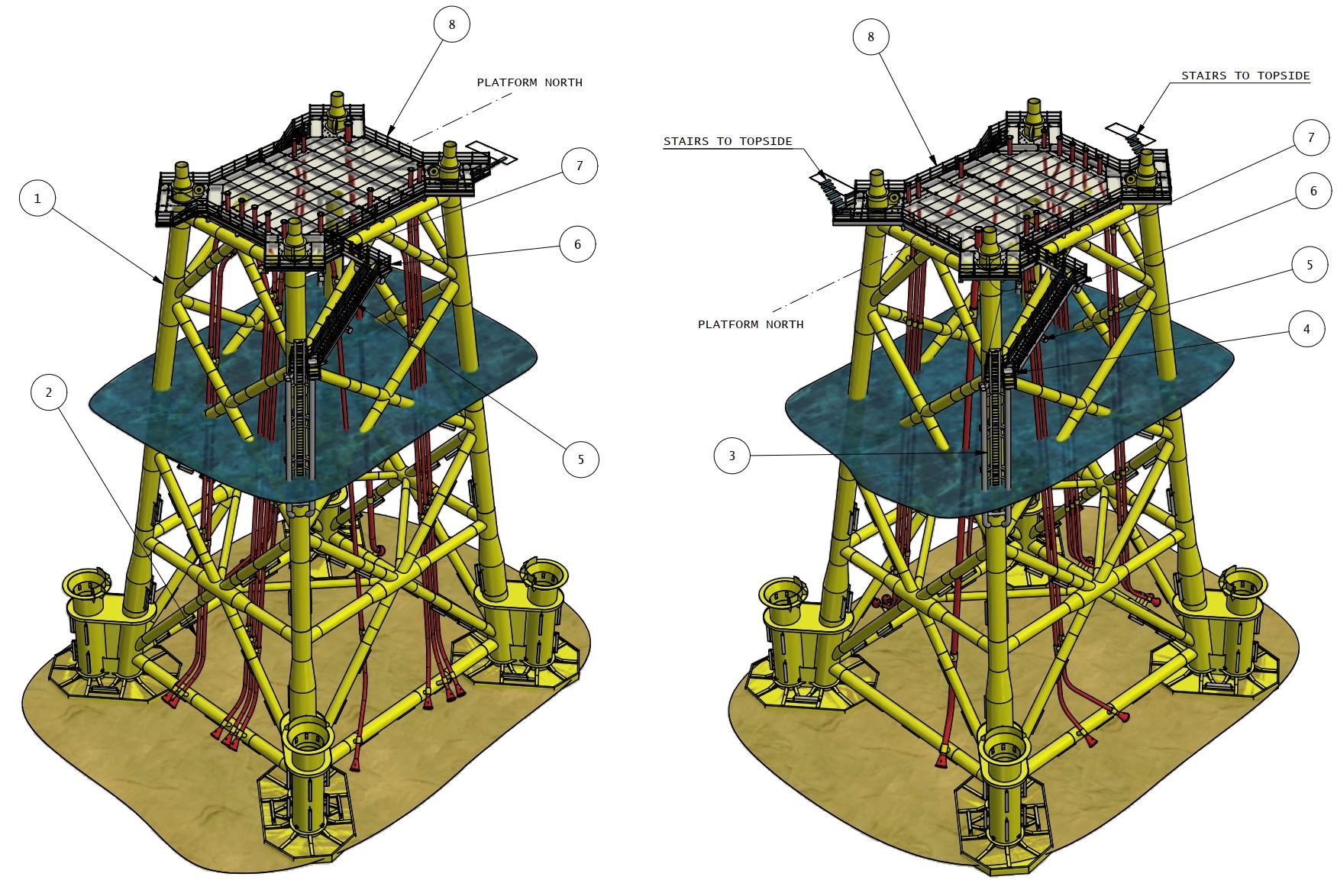

Topside structure – Monotower

LIC has designed the monopile foundations for a number of marginal oil and gas platforms in the Southern North SDea, water depth around 30 m. The work included riser Access towers (RAT) and on occasions the actual topside structure including interface to the monotower was part of detailed LIC design.

Topside structure – OHVS jacket structure

LIC has designed a Offshore High Voltage Station (OHVS) jacket structure for Chinese waters including the cable deck. The deck was designed to be build on ground and then lifted/welded in position on top of the jacket structure prior to load-out.