Subsea Pipelines

Design and engineering services – new pipeline projects as well as modifications and repair

Left foto: Pipeline installation in the North using reeling vessel and J-lay ramp. LICengineering typically supplies conceptual and detailed pipeline design as well as installation related engineering. Right fotos from the top: 1) Welding of concrete coated pipeline sections on lay-barge. 2) Lay-down test-head for subsea pipeline termination. LIC delivers services within precommissioning engineering. 3) Traditional pipe-lay using stinger to control the bend radius of the pipeline. LIC is deeply involved with design and engineering for large oil and gas trunk lines in the North sea.

LICengineering provides engineering during all phases of the design of subsea pipelines, starting from of site investigations, conceptual through to detailed design, detailed drawings, fabrication, transport, installation.

LICengineering carried out detailed design on majority of the subsea pipelines in the Danish part of the North Sea and in selected other pipelines projects worldwide.

Our designs are carried out in accordance to newest standards combined with state of the art knowhow and simulations tools. Furthermore, we do our design in a close collaboration with the client’s technical staff, including fabrication and installation teams, in order to get the optimum design at lowest cost.

LICengineering has expertise within specialized pipeline disciplines including route design, pipeline expansion design, tie-in design, upheaval buckling including subsidence effects, vortex shedding and free spanning, scour and seabed protection design, pipeline coating and cathodic protection, pipeline pre-commissioning, pipeline pigging and flow assurance.

Spool Design

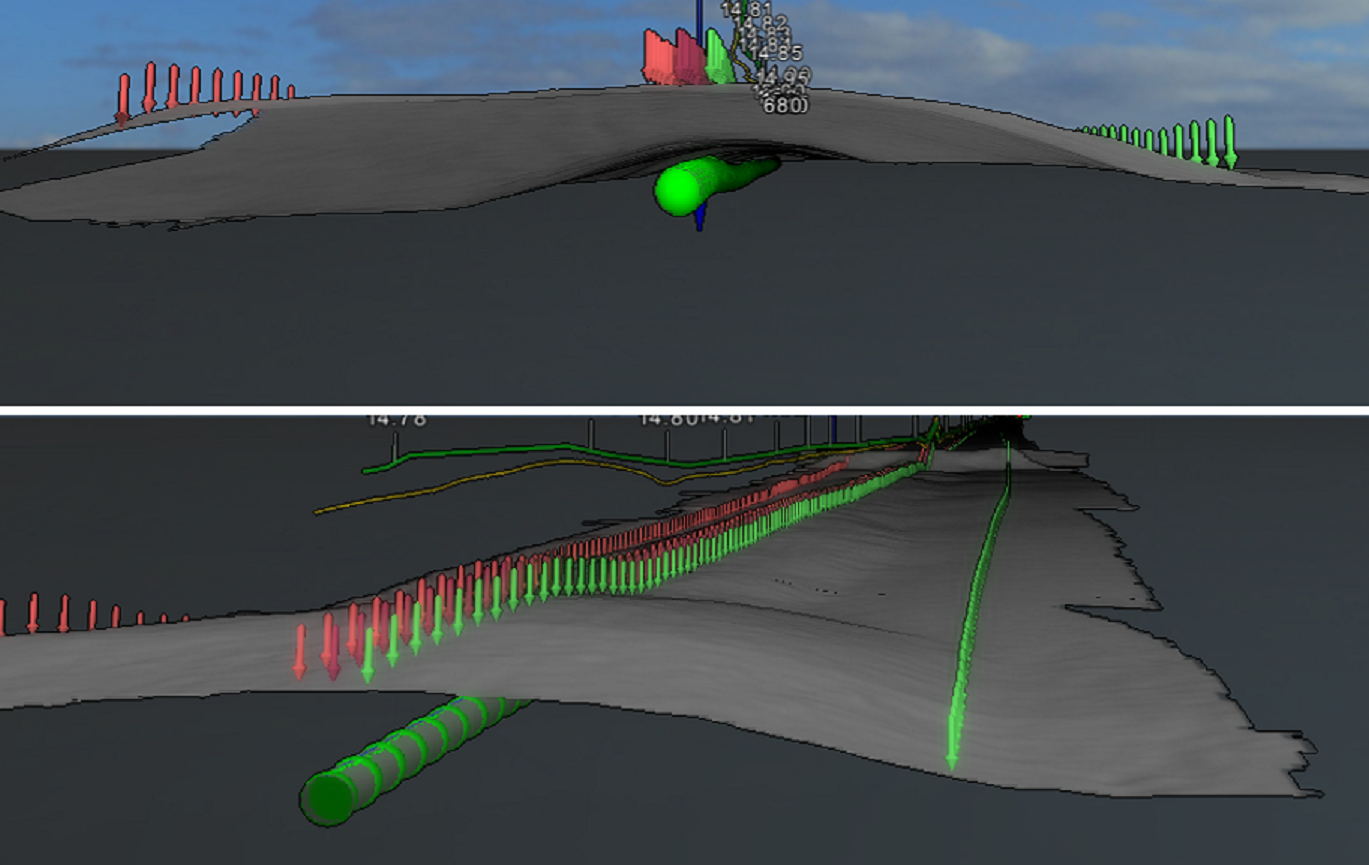

Installation of subsea expansion spool. LICengineering provides detailed design and analysis including spool geometry, pipeline expansion, spool protection, spanning and tie-in/installation engineering.

Subsea Pipeline Configuration

Pipeline and pipeline protection survey data are used for detailed engineering analyses.

The 3D models are used to asses required maintenance work as well as provide accurate basis for the structural analysis of buried pipeline.