Oil & Gas Energy

Repair & Modifications

LICengineering is often engaged in repair design activities on ad hoc basis. Typical engagements are within, subsea repair, topside structural repair, replacement engineering, design of repair components, supply of diving and topside work procedures, stand-by engineering assistance during work.

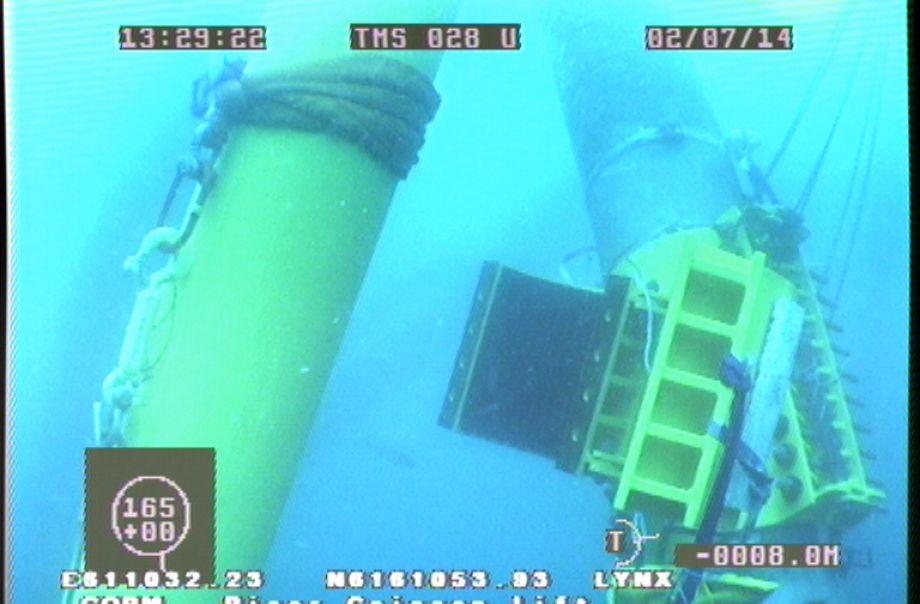

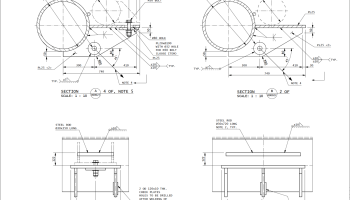

Left foto: Subsea repair clamp installation for corroded existing clamps. Right fotos from the top: 1) Repair clamps for strengthening of topside pipe supports. 2) Use of drilling connectors for repair of cooling water caisson on an offshore process platform. Work engineered by LIC to be done with sectional change out of the caissons, thereby avoiding requirement for diver intervention and ROV work inside the jacket truss structure. 3) Morgrip connector.

LICengineering has been deeply involved in a significant number of repair and modification jobs within the offshore oil/gas and subsea sector. The activity is typically to supply the detailed design and provide installation engineering including offshore work procedures. Some examples are listed below:

- Replacement and strengthening of existing riser clamp systems

- Pump and dump caisson repair, including lining of caissons, diver less installation in sections and use of drilling connectors

- Jacket boat fender removal

- Fast rescue craft boat landing, post installed on jacket leg

- Change out of escape ladders, offshore jackets

- Change out of components on existing subsea systems, such as valve actuator replacement

- Riser Repair Clamps

- Bridge bearing replacement, fixed offshore module bridges

- Pipeline and seabed scour rectification

- Design of deck extensions for offshore jacket

- Rectification of jack-up system

- Grouting of platform legs, design of intervention hose system, prepare offshore procedures